Lockout Tagout Facility Deployment |

Once the initial survey is complete, the next step in the process is to conduct the overall Lockout Tagout Facility Deployment. During an onsite visit, Steptron Technologies Surveyors will identify and document each piece of equipment along with it’s location, I.D number, and energy lockout points. In addition, they will

sketch a detailed graphical representation of each piece of equipment. Surveys will be completed for each system requiring Lockout Tagout procedures as required by OSHA regulations standard CFR 1910.147, the control of hazardous energy (Lockout/Tagout).

Each survey will identify primary and secondary hazardous energy with specific information as to where lockout devices are located, what the lockout device de-energizes, what it will not de-energize and how to verify the energy was removed. Associate energies fed from other systems/equipment will be identified as well.

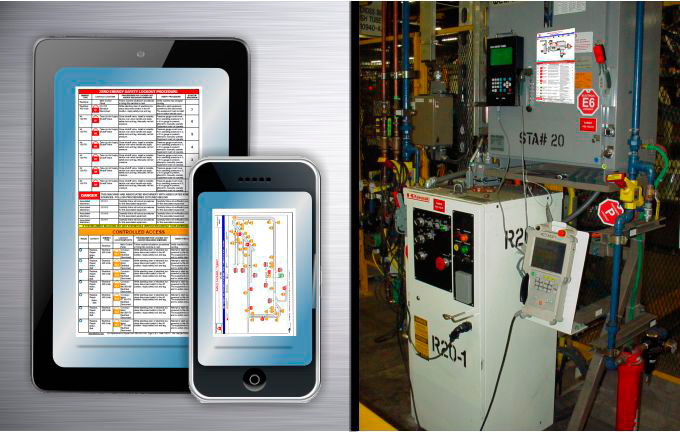

Once all equipment is surveyed, the information is sent to our manufacturing facility where our graphics team will generate graphical representations and procedures for each piece of equipment. Next our Surveyors will return onsite to perform a verification process with our clients. Once verification is complete, finals are produced by our production department and placards

and tags are installed. The final step in the process is employee training.

After 20 years in the business, Steptron has become very efficient at deploying Lockout Tagout solutions. Recently one of our largest clients stated “Steptron performs this service at one third the cost and time that it takes my staff to do it”.

|

|